Computer-aided design revolutionised the speed and efficiency of technical drawing and drafting. Gone were the days of drawing boards and rulers, replaced by software that could create detailed and accurate designs and specifications used by architects, product designers and engineers.

As the potential for this kind of software was realised, its applications grew from 2D drawing to 3D modelling. Two top-rated programs for both of these tasks are AutoCAD and SOLIDWORKS, used by individuals across a range of industries including electronic and embedded systems engineering.

If you work in a job that involves computer-aided design software, you’ll likely have heard of both AutoCAD and SOLIDWORKS. In this article, we explain the advantages and disadvantages of each, some of the key differences, and the situations and tasks that each program is better suited for.

What is AutoCAD?

AutoCAD is a widely-recognised piece of computer-aided design software that is a favourite program for drawing 2D designs. You can create all kinds of geometric models using the tools and features of the program, and it’s widely used not only by designers but also by engineers, architects, and graphical artists.

The first version of AutoCAD was designed by a team led by programmer John Walker, based on software previously created by Michael Riddle. They were both a part of the American multinational software company Autodesk, which continued to develop the program after Walker left, led by Carol Bartz, and created the version that gained international acclaim.

AutoCAD was one of the first pieces of design software that helped to automate the 2D drafting and drawing process created just for PC use, which revolutionised the design industry. 3D features were later developed on AutoCAD so that it can be used for this kind of design as well, but the software is mainly used for its 2D modelling properties.

The 2D functions of AutoCAD allow you to do classic design tasks such as creating design drawings and visualising different sections and views of a design, as well as other features such as creating parametric constraints for a design, linking Excel data with a live AutoCAD file, and revise individual sections of a design without having to create a new version.

You can also use 3D functions on AutoCAD for modelling, cloud rendering and product documentation. 3D modelling options for the software continue to be developed, but it is still mainly seen as a 2D modelling program.

Advantages of AutoCAD

- Using AutoCAD to create designs and plans is immensely faster than trying to draw them by hand or using other design software

- Since AutoCAD is used as the standard for computer-aided design, other files from CAD software tend to be compatible

- The user interface is considered to be very easy to navigate and understand, so it’s quite straightforward to learn AutoCAD

- A huge advantage of AutoCAD for designers is that it allows you to draw to scale and see the actual size of the product you’re creating

- Data on AutoCAD is stored very securely and can also be accessed by multiple people at once, allowing for easy collaboration on designs

- The software has a scanning tool that allows you to accurately calculate the quantity of the material you’ll need to produce the design, which can help to improve the production process

- The software allows users to use a Point Cloud as a starting point for designs

- PDF imports are processed with several features that make for easier editing, such as converting geometries to text objects

Disadvantages of AutoCAD

- Some specialised tools on AutoCAD are only compatible with Windows operating systems

- Editing the lines drawn on AutoCAD is much more of a hassle than other drawing and illustration software, which some designers might find frustrating

- The large number of functions on the program means that it can take a while to get to grips with all the different features

- AutoCAD isn’t a parametric design program, meaning that designs aren’t automatically adjusted when one component is edited

- The number of file formats that can be imported and exported on AutoCAD is quite limited

- Colour and texture options on AutoCAD are quite limited in comparison to other programs

- Registering for AutoCAD software is quite expensive, and the annual subscription fee is also fairly pricey

- Strong computer processing power is required for the software to run properly

- The 3D modelling software is quite limited in comparison to programs like SOLIDWORKS

What is SOLIDWORKS?

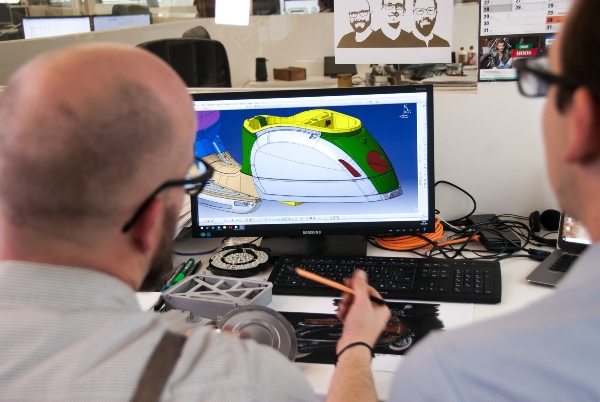

SOLIDWORKS is a piece of industry-leading CAD software that is best known for its 3D modelling tools. It’s incredibly popular among designers and engineers for its range of features and applications and has great functionality which means it’s used across all kinds of industries.

The software was first developed in 1995 by an MIT graduate called Jon Hirschtick. He was part of the well-known MIT Blackjack Team and wanted to create a 3D CAD program that was affordable for other graduates like himself.

In 1997, SOLIDWORKS was bought by an aviation manufacturing company called Dassault, where Hirschtick worked for 14 years. This is one of the main reasons why SOLIDWORKS is such a popular piece of software for mechanical engineers, even though it was designed with many different applications in mind.

SOLIDWORKS uses parametric design, which allows the user to see how changes they make to one component will affect the others around it, making it easier to spot and rectify mistakes. A library of templates and automation tools makes the design process faster and more efficient, and there are also tools for creating animations and rendering designs using SOLIDWORKS Visualise to get a clearer idea of what they will look like in real life.

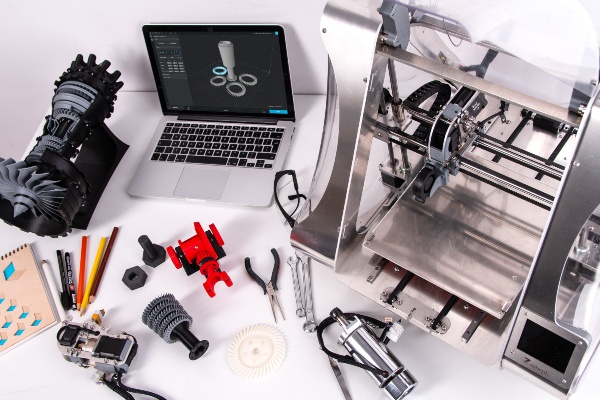

You can also use SOLIDWORKS Simulation to virtually test designs and collect performance data, which helps the user to rectify problems in the early stages of a design project and save time later on. There’s also a feature that converts a SOLIDWORKS design into files that can be sent straight to a manufacturer, allowing for ease through the entire product lifecycle.

The versatility of SOLIDWORKS’ features means that it’s used in all kinds of professions, but transport, aerospace, defence, energy and consumer goods are the most common sectors where the software is used. Mechanical, design, product and electronic engineers are some of the top roles that regularly make use of SOLIDWORKS.

Advantages of SOLIDWORKS

- Many users agree that SOLIDWORKS is quite easy to get to grips with, even as a complete beginner

- There are also lots of tutorials for SOLIDWORKS that have already been created by the community, making it easy to find help if you need it

- The parametric nature of the software makes it easier to adapt an overall design if you’ve made changes to one part of it

- It’s much easier to create product documentation for design on SOLIDWORKS as the software makes the majority of the calculations and measurements for you

- SOLIDWORKS models can instantly be read by computer numerical control (CNC) machines and 3D printers without the files having to be converted

- There are templates for standard components in SOLIDWORKS, saving you lots of time if these are part of your design

- SOLIDWORKS projects are accessible by multiple people, making collaboration easy

Disadvantages of SOLIDWORKS

- SOLIDWORKS is only compatible with Windows operating systems, making it much more difficult for designers that use Mac OS

- There’s pretty limited 2D functionality if you’re creating flat designs with SOLIDWORKS

- The quality of image rendering doesn’t compare to other CAD programs

- If you want to make a drawing using raw data, the design doesn’t tend to be very detailed

- The cost of the SOLIDWORKS annual subscription and initial licence investment is high, making this option inaccessible for many individuals

What are the Differences Between AutoCAD and SOLIDWORKS?

There are plenty of differences when it comes down to AutoCAD vs SOLIDWORKS, which is mainly due to the fact that the programs were designed for different things.

AutoCAD was originally created for 2D design modelling, whilst SOLIDWORKS was designed with 3D modelling in mind. Both programs offer the option to design in both 2D and 3D, but these features aren’t really comparable because AutoCAD is the standard 2D choice and SOLIDWORKS is the standard 3D choice.

Another key difference in the SOLIDWORKS vs AutoCAD debate is that SOLIDWORKS is parametric whilst AutoCAD is non-parametric. This means that when you alter a design’s parameters in SOLIDWORKS in one section, the rest of the design is automatically updated, whereas you’ll need to do this manually if using AutoCAD.

AutoCAD was originally designed to be used for architectural design and construction documentation, but later became widely used in mechanical, structural and electrical engineering sectors. In contrast, SOLIDWORKS was designed with mechanical, automotive and aerospace engineering in mind from the beginning, and only later began to be used in an architectural and electronic engineering context.

To drill down into a particular industry sector, we can look at the specific electronic engineering programs designed by SOLIDWORKS and AutoCAD. When comparing SOLIDWORKS Electrical vs AutoCAD Electrical, the main difference is that SOLIDWORKS Electrical has been more recently updated and therefore is more streamlined and has better features, whilst AutoCAD Electrical is useful but hasn’t quite caught up in terms of functionality.

SOLIDWORKS software has a much more complex user interface. AutoCAD is pretty accessible for total beginners, whilst SOLIDWORKS is designed for those with more experience and takes a lot longer to get to grips with.

When it comes to accessibility, SOLIDWORKS CAD software is currently only available in the English language, whereas AutoCAD is available in many other languages. This makes it much harder to learn to use the software if you don’t speak English, or means that you’ll need to find an alternative in your language.

Should I Use AutoCAD or SOLIDWORKS?

Since the two programs are quite different, choosing whether to use AutoCAD or SOLIDWORKS is quite a straightforward decision.

If you need to create a 2D design drawing, AutoCAD is the best piece of software out there. SOLIDWORKS is much better for creating 3D parts and products thanks to the functions that let you see different angles, render the design and run simulations.

Speaking of simulations, SOLIDWORKS is the best choice if you want to put your design through motion simulation, animation and rendering. AutoCAD, on the other hand, is the better piece of software if you’re looking for a general drafting platform.

AutoCAD is the best program for mechanical architecture and civil engineering, whilst SOLIDWORKS is best for mechanical engineering and electronics engineering. We’ve already mentioned how SOLIDWORKS Electrical is the better industry-specific program out of the two, so if you’re looking for which to choose for electronic design, opt for SOLIDWORKS.

Summary

Both SOLIDWORKS software and AutoCAD programs are very valuable tools for electronic engineers to use, so at the end of the day feeling comfortable using both of them is probably your best course of action. However, if it comes to choosing one piece of software, consider the task that you’re doing and the features that each program offers, and make your decision based on which one is better suited to meet your needs.

If you’re an electronic engineer with AutoCAD or SOLIDWORKS experience, we’re a specialist recruitment agency that can help you find roles that make the most of these skills. View our available job opportunities or get in touch to speak to our team about how we can help.